Our Products

Whether our clients wanted tilt-up construction or a blend of concrete construction and steel buildings for their commercial project, we have it.

Liftcore Jumpform

Is a flexible formwork for confining concrete liftcore wall on the construction of high rise buildings that saves time, labour and cost.

Advantages of the system

- The form work elements are joined together and lifted as a unit to allow the concrete wall formed during the next stage to be exactly the same as the previous one.

- It allow the construction of the concrete wall 3 floor ahead prior to that of the floor slab, saving manpower and time of construction.

- The operation is simple and can be operated by non-skill labours.

These allow the work to be completed in the shortest time and at a minimum cost with high quality.

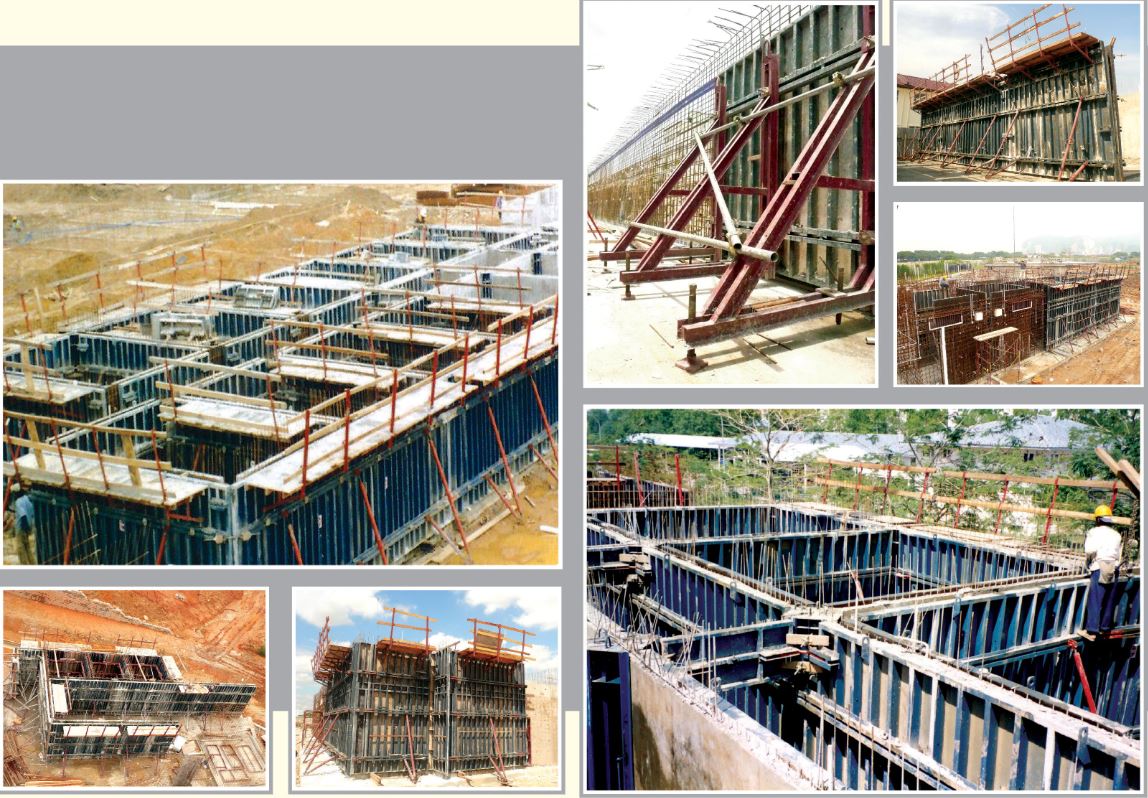

Steel Wallform System

Allows large area of concrete wall to be formed easily, precisely and completed within a limited time. By using HIFORM wallform system, high quality concrete walls can be obtained by none skill labours with minimum work force.

Advantages of the system

The steel wallform system provided by HIFORM is formed by joininh elements of standard wall panel with shutter connector.

All forming surface are using 4mm thick mild steel plate therefore they can be reused again in many different projects.

This result in quality, recycle & reuse, save money & time.

Plywood Face Wallform System

Where complicated sections are to be constructed and the standard formwork cannot be applied, PLYWOOD FACE WALLFORM will be supplied to complete the work.

Advantages of the system

- Plywood is lighter than steel and can be handled easily.

- It provides a neater finish on the surface of the finished concrete.

- Plywood has a high strength that makes it a suitable material for formwork system.

All these factors contribute to the saving in labour cost and provide quality work.

Column Form System

(A) Adjustable Steel Column Form System (Steel Surface)

Steel Columns – Rectangular or Square shape

Each column is formed by four steel panel sections connected by locking devices at the joints that can be adjusted easily at the water to formed any shape required.

Steel Columns – Circular shape

Each of these consists of two half shells with fitted bolts at the joints. Push-pull props are installed to provide vertical alignment for the formwork.

(B) Column Form System (Plywood Surface)

Hiform’s Column Form System utilizes lipped channel of RHS with column walers in two parts – male and female which are connected by tension pins to form square and rectangular columns.

As several types of standard column walers have been fabricated and ready for services, a column of any size and height can be formed accurately. Push-pull props are installed that provide easy and fast alignment. Each column can be lifted in two halves or as a single unit easily.

Telescopic Beam System

It is a horizontal-support beam specially designed with high strength for an overall rationalization of concrete slab construction.

Advantages of the system

- Versatile with slab width

- Easy to handle with little skill or experience

- No propping is required at mid span.

- Can be applied to elevated bridge and high rise constructions.

- Steel composite structure can be applied for load bearing slabs

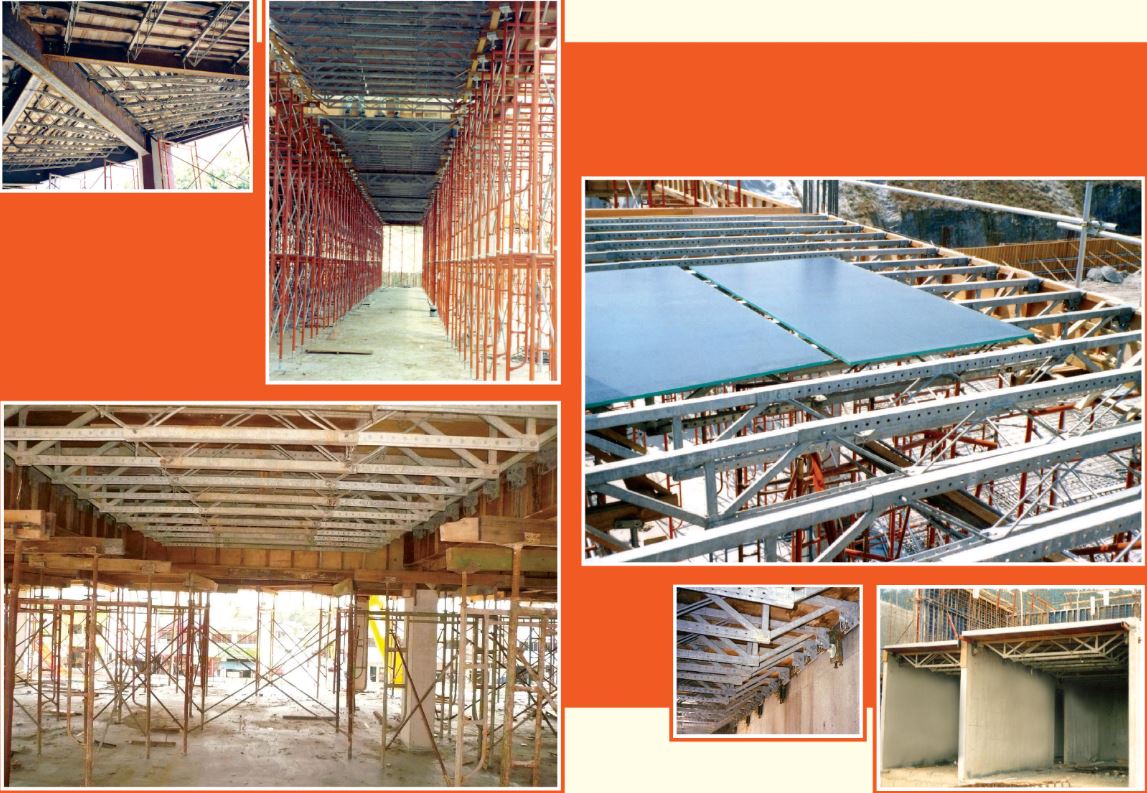

Steel Truss Tableform System

It is a suitable for high-rise constructions. Relatively quick turn-around time for striking, flying and resetting to enable it to achieve a shorter construction cycle with minimum manpower.

Advantages of the system

- Enables slab construction using large flying table form

- Adjustment in height can be done quickly to pick up internal beams or spandrels.

- Can be formed into table of larger size.

- Economical, as it is light weight yet can support heavier load, high mobility, fast to be fixed and removed.

Tunnelform System

It is a cell system made entirely of steel and with all its load-bearing parts possessing great rigidity.

Advantages of the system

- Perfect flat wall and soffit surface can be formed.

- Dimensional accuracy is ensured

- Maximum progress with minimum labour

- Recycle & Reuse.

Silo & Tower Jumpform System

It is a flexible formwork for confining concrete wall on the construction of silo that saves time, labour and cost.

Advantages of the system

- The formwork elements are joined together and lifted as a unit to allow the concrete wall formed during the next stage to be exactly the same as the previous one.

- It allows the construction of the concrete wall free standing hence, saving time of construction.

These allow the work to be completed in the shortest time and at a minimum cost with high quality.

Metal Form

Different types if Metal Form are fabricated for the constructions of walls, columns, beams, and slabs. They are accurate, durable and cut down working time and cost of construction. They are supplied in many forms, shaped and sizes according the job requirement. It minimize usage on crane and all panel can be hand held easily.

Special Precast Mould

All special precast mould can be fabricated for the construction of staircase with landing, column, beam and slab. The precast mould can be recycle and reuse many time. Hence that it could save money for contractor.

Custom Made Mould

HIFORM also supplies steel custom made mould of any sizes and shapes to meet any requirement.